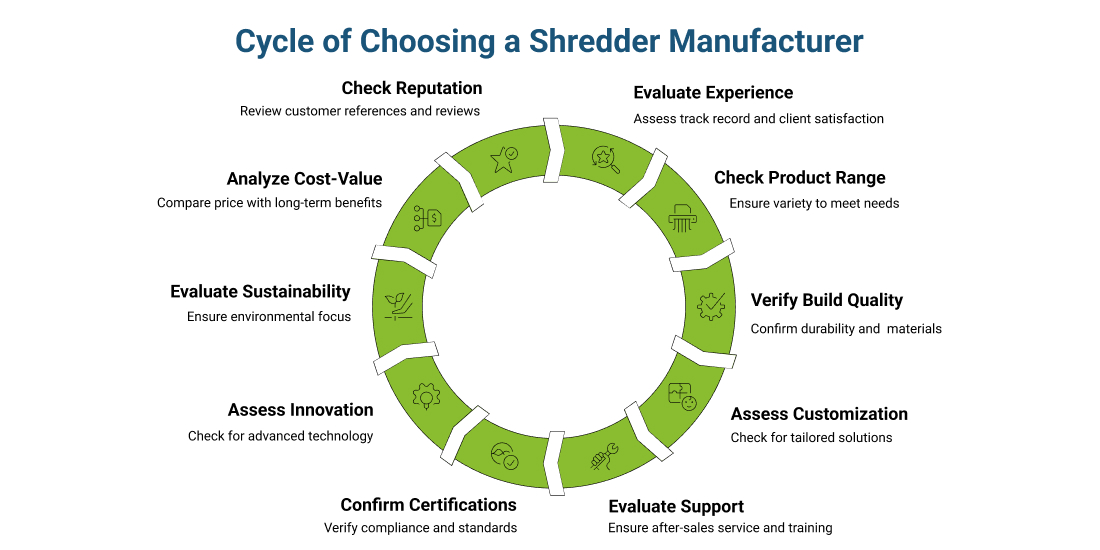

Choosing the right shredder machine manufacturer plays a very important role in the waste management and recycling process. A good manufacturer will not only know your industry’s requirements but also produce a heavy-duty, industrial shredder machine that will work during heavy-duty operations and last for years. This blog gives you ten important features that you should always consider before choosing a manufacturer. We shall discuss factors like product variations, build quality, service, and sustainability that will assist you in making an informed decision.

1. Based on Experience and Proven Industry Track Record

The leading shredder machine manufacturer has an impeccable track record in the shredder industry. You can always start your search by looking for companies that have many years of experience, have very high numbers of installations, and have clients from all sectors, and who are happy with their services. Skilled manufacturers are already familiar with the various types of waste streams, be it e-waste, metal, or organic waste, and will be able to guide you to the suitable waste shredder machine.

For instance, the shredder machine manufacturer may frequently mention the references and case studies they have used to signify their credibility. It is advisable to always inquire about past projects that are like yours and to read client reviews. A manufacturer who has been in business for a long time and has a solid reputation (as shown by good reviews) will be more likely to provide a dependable shredder machine as compared to a startup.

2. Comprehensive Product Range and Technical Capability of Shredder Machine Manufacturer

The shredder machine manufacturer that is trustworthy presents a variety of shredders to meet the needs of different applications. In addition to single-shaft and twin-shaft designs, they also provide machines for plastics, metals, e-waste, and general waste. For instance, the most prominent suppliers usually present single-shaft units (10-25 HP for heavy-duty shredding) and twin-shaft ones (5-50 HP) to serve the needs ranging from small to very high capacity. The product range of the manufacturer must include single-shaft shredder machines (suitable for uniform materials) as well as twin-shaft shredder machines that are intended for mixed municipal or industrial waste.

Manufacturers are also expected to offer industrial shredder machines, heavy-duty shredder machines, and high-capacity shredder machines if your application requires them. Having a wide range of products means that the manufacturer can create solutions – whether it is a small plastic shredder or a heavy-duty metal crusher – without relying on external suppliers.

You can also read our guide on how to find the best shredder machine manufacturer for your industry for deeper insights.

3. High Build Quality and Durability

Using high-quality materials and robust construction is a must. A dependable shredder should consist of hardened steel blades, powerful gearboxes, and a strong frame to withstand constant usage. Look for the terms “heavy-duty” and “industrial strength” in their product descriptions.

For example, EnvCure’s twin-shaft models highlight medium to heavy-duty waste management and the ability to work with tough materials such as tires and metal pieces. Usually, these machines come with choices for wear-resistant blade materials and strong shafts. High-quality construction means low repair and maintenance costs during the operation of the shredder: proper design and long-lasting components lead to longer blade life and fewer breakdowns. Before making a purchase decision, check that the specifications (chamber size, blade thickness, motor power) conform to your needs; the top shredder machine manufacturer will clearly list these details.

4. Customization and Tailored Solutions of Shredder Machine Manufacturer

Different waste streams require different approaches; thus, a shredder with the same characteristics for every application may not be the best solution. A trustworthy shredder machine manufacturer provides customized shredder machines, like special blade designs, exclusive feed hoppers, or integrated conveyor systems, to cater to your needs specifically.

For instance, custom knives intended for the plastic recycling process can increase the output up to twice, and the conveyor systems made as per the requirements can make the operation smoother. The top vendors collaborate with customers to build the precise system: whether it is a unique dual-shaft shredder for electronic waste or a modified single-shaft machine for oversized packaging. In short, they not only sell ready-to-use models; they configure industrial shredder machines according to your waste type and process flow, thus turning a good machine into a great one.

5. Strong After-Sales Service and Support

Buying a shredder is an investment, so after-sales support is of great importance. A trustworthy shredder machine manufacturer will provide installation, operation, and maintenance services for its machines. Look out for services like on-site commissioning, operator training, and spare parts always available. The better the manufacturer, the faster the service, and the more downtime is reduced (even remote diagnostics).

For instance, EnvCure’s method comprises on-site repairs and operator training in order to keep the machines operating smoothly. Inquire about the warranty period and the specifics of what is covered under it. The selection of a maker with a proven service department is your assurance that your heavy-duty shredder machine will always be in premium condition, long after the purchase.

To understand how the right machine can directly cut your operational costs, you can also read our detailed guide on how a waste shredder machine reduces landfill volume.

6. Quality Certifications and Compliance

Certifications represent the shredder machine manufacturer’s quality dedication. Trustworthy shredder manufacturers typically hold ISO 9001, CE, or specific industry certifications (e.g., R2 for electronic waste) as proof. This means the shredder is to a certain standard regarding safety, performance, and the environment.

For example, certified shredders in the industry provide the same quality as the production. In waste management, safety regulations (e.g. for metal recycling or e-waste) compliance is vital. A firm that points out ISO or CE certification indicates that it practices. It is a good practice to be skeptical about suppliers not having any standards documented; certifications can be an indication that the manufacturer is committed to safety and reliability.

7. Innovation and Advanced Technology

The top manufacturers are constantly working on R&D to bring forth the next generation of more efficient, safer, and user-friendly machines. Automated lubrication, smart sensors, and motors that consume less power are among the highlighted features. To illustrate, the state-of-the-art shredders could be equipped with automatic oiling systems that would take care of lubricating the blades without the need for a person to do the job, and this would not just improve safety but also cut down on maintenance.

Besides, load indicators and auto-reverse functions are there to prevent jams. An innovative manufacturer will use technologies like PLC controls or IoT monitoring that result in a shredder with low maintenance. In brief, modern designs with automation and safety interlocks not only boost performance but also reduce downtime – an attribute of a supplier that is committed to providing long-term value.

8. Environmental Focus and Sustainability

A good shredder machine manufacturer knows that shredding is an important factor in the process of waste reduction and recycling. Their machines should be able to help you achieve environmental objectives like reducing landfill volume or recycling more materials. For instance, the separation of mixed waste into small pieces not only aids recycling but also saves the cost of transport up to 50%. Producers of shredders usually stress the fact that their devices are contributing to a circular economy.

Numerous ones mention advantages such as “better waste management” and “higher recycling efficiency” in their promotional materials. Check if the producer deals with plastics, metals, electronic waste, and organic waste – doing so proves that their machine is suitable for different recycling processes. The use of an eco-friendly technique (like energy-saving motors and options for separating waste) is a plus.

9. Cost vs. Long-Term Value

The price is a major factor, although the cheapest shredder will usually be the one to incur the most possible costs during its life cycle. A reliable manufacturer can prove the ROI (return on investment) for a shredder. Heavy-duty, high-capacity shredders would be the choice for those who see the future long-term value rather than the upfront cost.

For example, a well-designed twin-shaft shredder can be self-financed within two years thanks to lowered labor and disposal costs. Low-cost suppliers cutting corners on materials or service will be the ones to be avoided. On the contrary, a quality manufacturer will be the one to encourage you “to look past the initial cost” and to consider energy and maintenance savings via. Case studies or calculations could be requested: the good manufacturers will very often be the ones to reveal how their clients recoup costs by shredding more efficiently and reducing landfill fees.

10. Reputation and Customer References of a Reliable Shredder Machine Manufacturer

At last, reliable makers possess proof of their customers’ satisfaction. Look for case studies, client lists, or testimonials, as well as independent reviews. A trustworthy shredder machine manufacturer will not hesitate to disclose the success stories (for instance, installations in schools, cities, or factories) that testify to their worth. If it is feasible, contact the past customers and ask them about their experiences. A strong endorsement for the company’s support, communication, and product quality is a good sign. One industry review notes that confirming a manufacturer’s reputation – including long-term experience and customer satisfaction – is very important when selecting industrial shredders. Do not overlook this step; feedback from peers often brings to light problems (such as maintenance delays or noise levels) that are not apparent in written forms.

To conclude, the partnership with a shredder machine manufacturer will provide the users with an efficient, durable, and compliant shredding solution. The point manufacturers are to be certified, have custom solutions, after-sales support, and a good record in the field, among the questions to be asked before deciding on a manufacturer.

Conclusion

In conclusion, a reliable partner for shredder machines will have no problem in all these aspects. For instance, EnvCure Technocrat LLP – the top shredder machine manufacturer in India, has a lot of these traits, starting with the sturdy single- and twin-shaft models and leading right up to excellent customer service. By assessing the manufacturers against the mentioned criteria, the customers can confidently invest in a shredder that will serve them well for many years.

FAQ Related to Shredder Machine Manufacturer:

Q: How do I know if a shredder machine manufacturer is reliable?

A: Check out the manufacturer’s experience, client testimonials, and certifications like ISO 9001 or CE. Reliable manufacturers usually have a strong track record and a good reputation.

Q: Are custom shredder solutions worth it?

A: Yes, custom shredder solutions improve efficiency by tailoring blades and systems to your specific waste type and volume, often boosting throughput compared to generic models.

Q: What kind of after-sales support should I expect?

A: Expect installation, operator training, spare parts, and prompt service. Good manufacturers may also offer preventive maintenance, remote diagnostics, and a clear warranty to ensure smooth operation.

Q: What certifications and standards matter for shredders?

A: Look for ISO 9001, CE marking, and relevant compliance labels (like R2 or e-Stewards). These certifications indicate quality, safety, and regulatory compliance.

Q: Why should I consider the manufacturer’s location? (e.g., choosing a shredder machine manufacturer in India)

A: Local or regional manufacturers like EnvCure Technocrat LLP offer faster support and lower shipping costs. Evaluate them on quality, service, and capacity; if they meet these criteria, they can be an excellent choice.