Food Waste Disposer, often referred to as Food Waste Crusher or Commercial Food Waste Grinder Machines, are heavy-duty devices capable of handling large-scale organic waste generated in commercial kitchens, canteens, and restaurants. On a day-to-day basis, these appliances are used in busy commercial kitchens and canteens to dispose of vegetable peels, meat trimmings, leftover plates, etc. They grind the waste and flush it down the drain into sewage or the digester.

This guide talks about the procedures industrial food waste disposers follow, their advantages (like hygiene, cost, and environmental benefits), and the aspects to consider when selecting the proper model (such as capacity, motor, and durable material), also including installation and maintenance directions, projected investment cost versus ROI, and problems along with their solutions.

The Process of Food Waste Disposers in Commercial Kitchens

- A commercial food waste disposer is a standalone machine that grinds organic waste using a high-power motor and a robust grinding chamber.

- Kitchen staff can drop food scraps directly into the disposer opening of continuous-feed models, while running water helps flush them down the drain.

- Inside the unit, a high-torque motor spins a turntable or impeller fitted with stainless steel blades, crushing waste into 1–5 mm.

- These fine particles are either:

-

- Washed through the plumbing system (usually via a grease interceptor or sewer), or

-

- Collected separately for composting or biogas production.

- Premium models are built with stainless steel components for durability and include safety features such as overload protection and anti-jamming mechanisms.

- Modern food waste disposers are designed to minimize water consumption, up to 70% less than older models, and to operate quietly.

- The entire grinding process typically takes just a few seconds, allowing high-volume kitchens and canteens to dispose of large quantities of waste almost instantly.

Key Benefits of Food Waste Disposer for Restaurants and Canteens

The installation of a food waste disposer results in the kitchens of food service and institutions reaping numerous benefits:

- Reduced waste: The disposal of scraps reduces the volume of waste produced by up to 50% thereby minimizing he space and frequency needed for waste bins to a great extent.

- Hygienic: The process of instantly removing scraps eliminates the presence of spilled and leftover food in bins. The foul smell is cut, and pests (rats, flies) are discouraged; thus, the result is a cleaner, safer kitchen.

- Cost of disposal lowered: The reduction in the volume of waste leads to a decrease in the number of dumpster pick-ups and thus lower tipping fees. In fact, waste hauling might be a costly affair, consuming several percent of a restaurant’s budget. Therefore, cutting it down to half can mean significant savings.

- Salaries of workers saved: The staff have to spend less time on food waste handling, transporting, and cleaning up. The machine does the source separation automatically, thus allowing the workers to concentrate on cooking. This process eliminates heavy lifting and messy tasks, enhancing productivity.

- Speed in operation: The cleanup after the service of meals is quicker. In cases of buffet or banquet settings, the kitchen crusher disposers allow the staff to clear plates and prep stations at once, which is of utmost importance during rush hours or big events.

- Environmental Impact: Disposing of organic scraps in landfills is one of the major actions that dispensers do, which really helps in achieving sustainability. The landfills’ volume is reduced, hence less methane is released, and makes waste is pre-ground for easier recycling in anaerobic digesters or composters. For example, up to 1,400 homes may get their annual energy from the conversion of 100 tons of food waste per day to biogas.

The collection of these benefits indicates that disposers are an intelligent investment. Research indicates that the return on every dollar invested in food waste crusher cutting remains high.

Want to know why more restaurants and hotels are investing in this technology? Explore our post on 10 Benefits of Installing a Food Waste Disposer in Your Restaurant or Hotel for key insights.

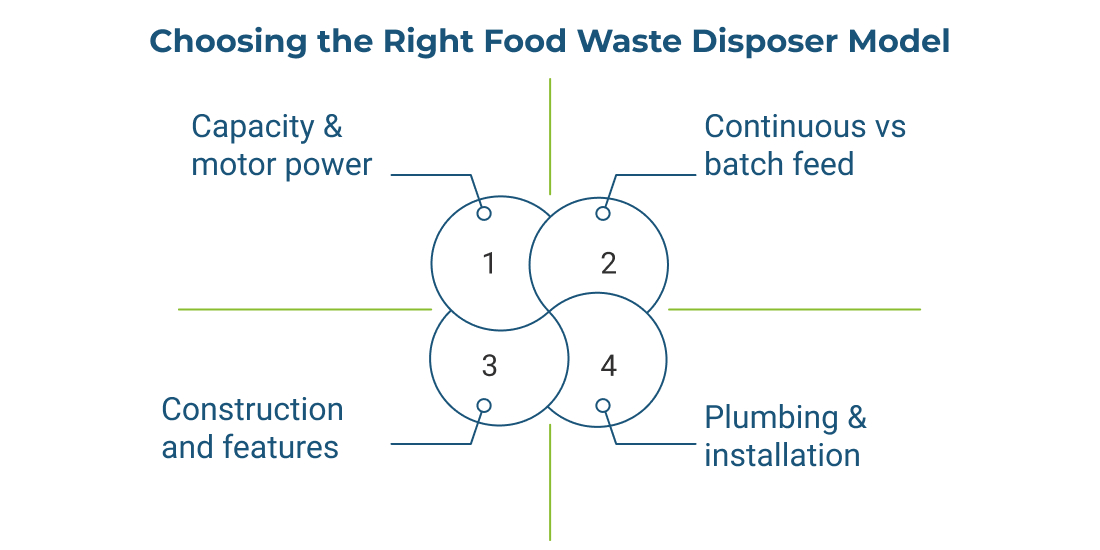

Choosing the Right Food Waste Disposer Model: Capacity, Motor & Build

Picking the best food waste disposer depends on your kitchen’s size and workload:

- Capacity & motor power: Estimate your daily food waste volume. Small cafés might get by with a 1–2 HP unit, whereas hotels and large canteens often need 2–3 HP (or higher) continuous-feed disposers to run all day. In general, larger kitchens or 24/7 operations require high-horsepower, three-phase motors to handle nonstop grinding. Many commercial food waste crushers are rated by grinding capacity (kg/hour) or horsepower (HP); match these to peak usage.

- Continuous vs batch feed: Continuous-feed models allow staff to feed scraps on the fly (ideal for large flows). Batch-feed units have a lid that must be locked in place (safer for smaller or lower-volume kitchens). Consult with manufacturers to determine the best feed style for your scenario.

- Construction and features: Look for a long-lasting build, usually a thick stainless steel or cast aluminum body that resists corrosion and wear. Besides, a solid motor base and heavy blades are critical for grinding bones and fibrous waste. Ensure safety measures such as overload protection, anti-jamming cutouts, and splash guards are in place. Consider also additional features like auto-reverse cycles or quiet motors. A quieter model might be very important in a busy kitchen; noisy disposers can be very annoying.

- Plumbing & installation: Ensure the disposer’s discharge is compatible with your sink/drain arrangement. Most of the big disposers require an extra-strength sink and a different power supply. It is a good idea to check if you need a grease interceptor or special venting to comply with local regulations. Most units come with standard mounting hardware for easy under-sink installation, but larger-capacity machines might still need professional plumbing support.

Always match the specification sheet (motor HP, RPM, amperage) to your electrical and physical setup. In summary, choose a food waste disposer whose rated daily capacity and motor horsepower comfortably exceed your kitchen’s demand, in a rugged package designed for continuous use.

To make an informed decision before purchasing, check out our blog on How to Choose the Right Food Waste Disposer for Your Business.

Installation & Maintenance Checklist

Installation:

- Professional plumber/electrician: A commercial food waste disposer usually requires a hardwired power connection (single or three-phase) and solid mounting. It is best to let the certified trades install the unit and connect it to a water source and drain/interceptor.

- Water supply: Disposers must have a continuous cold-water flow when operating. Either a flow switch is installed, or the sink faucet is used during grinding.

- Grease management: Even through grinding, fats should not go down the drain in large amounts. If necessary, use a grease trap or interceptor.

- Ventilation: Under the sink, provide ventilation to keep the motor cool and prevent overheating.

Daily/Weekly maintenance:

- Run water before/after use: Cold water must flush in the food waste disposer before waste loading, and also run for 15 seconds after grinding stops. This clears the pipes and prevents clogs.

- Keep it used: The internal parts are made to move, and corrosion is prevented. The disposers remain “maintenance-free” when used together with water.

- Clean with care: Avoid strong chemicals; if needed, use mild dish soap or a citrus-based cleaner. Do not use bleach or caustic drain cleaners. The blades can be sharpened by periodically grinding ice cubes and citrus peels.

- Safety checks: Leaks, loose fittings, or worn parts should be checked regularly. In case there’s a reset button (overload protector) on the unit, ensure it is not tripped.

For instance, the unit stopping mid-cycle likely triggered an overload. Turn off the power, remove any jam or large debris from the chamber, and then press the red reset button (usually at the bottom) to restart operation.

If you manage a restaurant or hotel kitchen, don’t miss our in-depth article on Commercial Food Waste Disposer for Hotels and Restaurants

Sustainability & Integration with Waste Systems

A food waste disposer fits into green kitchen strategies by diverting organic scraps from landfills and recycling them to useful ends. Instead of rotting in a bin, ground waste can be sent to anaerobic digesters to make biogas (renewable energy) and biofertilizer. In fact, EESI reports that anaerobic digestion of 100 tons of food waste daily can power 800–1,400 homes. Even smaller kitchens contribute when combined with municipal waste treatment; crushed organics generate methane for energy rather than emitting uncontrolled landfill gas.

For in-house or municipal composters, a food waste disposer provides pre-shredded feedstock that speeds up decomposition. Some commercial food waste crushers and kitchen pipe disposal effluent into on-site composting or digestion tanks, turning a kitchen cost center into a biogas source. All this helps meet sustainability goals and increasingly strict food waste regulations. (In fact, some regions may soon mandate in-sink disposers as a way to meet landfill diversion targets.) Overall, integrating a disposer is a step toward a circular waste system, conserving resources while reducing the carbon footprint of disposal.

Conclusion

A well-chosen food waste disposer can transform how canteens and commercial kitchens handle scraps – cutting waste volume, improving hygiene, and even turning organic waste into energy. By sizing the unit to your kitchen capacity and maintaining it properly, you’ll gain operational efficiencies and cost savings while supporting eco-friendly practices. To explore solutions tailored to your facility, contact EnvCure Technocrat LLP today for a quote or demo. Discover how EnvCure’s industrial food waste disposer can make your kitchen cleaner, greener, and more profitable.

FAQs Related to Commercial Food Waste Crusher:

Q.1. How does a commercial food waste disposer work?

Ans: Commercial units use high-torque motors and rotating blades to pulverize food waste. Cold water runs through while grinding, flushing the particles into drains or collection tanks for compost or biogas processing.

Q.2. What can I put in a food waste disposer?

Ans: Most biodegradable kitchen waste is suitable: vegetable and fruit peelings, small bones, eggshells, coffee grounds, dairy clippings, etc. Essentially any wet organic scrap (leftovers, meat scraps, produce) can go in.

Q.3. What should NOT go into a food waste disposer?

Ans: Non-food items (plastic, glass, metal, diapers, etc.) and very fibrous or starchy waste (e.g. large corn husks, celery strings, thick grease) should be avoided. These can clog or damage the machine. Only biodegradable, flushable scraps should be used.

Q.4. How much motor power (HP) do I need?

Ans: It depends on the volume. As a rule, higher-volume kitchens need larger motors. For example, a small restaurant might use a 1–2 HP unit, whereas large hotels or canteens may require 3 HP or more continuous-feed disposers. Larger motors handle heavier loads and longer run times without tripping.

Q.5. What are the main benefits of using a disposer?

Ans: Disposers reduce waste volume, improving sanitation and cutting disposal costs. They eliminate messy bins, decrease odors/pests, free up labor, and support eco-friendly practices. Simply put, they save money and time while boosting kitchen hygiene.