Many businesses in India wonder whether an Organic waste composter (a mechanical composting machine) or conventional composting is the better solution for their organic waste. Both approaches aim to turn food and garden scraps into compost, but they differ greatly in speed, space, odor control, and compliance. As Green planet solutions notes, “one of the most searched questions” today is comparing traditional composting vs. organic waste composter machines. In this guide we’ll define each method, compare them side-by-side, and help you decide which fits your hotel, hospital, campus or community best.

What is an Organic Waste Composter?

An Organic Waste Composter is a self-contained, often automated system that rapidly turns kitchen scraps and other biodegradable waste into finished compost. Unlike a simple compost pile, these machines use controlled heat, aeration and mixing to speed up decomposition. Typical features include:

- Fast Processing: Converts organic waste to compost in about 24–48 hours (versus months for an open pile).

- Enclosed Design: Sealed bins or drum chambers with odor filters and scrubbers keep smells and bugs contained.

- Compact Footprint: Uses around 10–100 m² of space, suitable for urban sites.

- Automatic Operation: Many models are push-button systems with built-in shredders and mixers, requiring minimal manual labor.

- Compliance-Ready: Engineered to meet waste rules (e.g. India’s FCO standards), reducing methane by treating waste on-site.

- Produces Quality Compost: Yields nutrient-rich, sanitized compost (often FCO-compliant) you can use or sell.

EnvCure Technocrat LLP designs organic waste composter machines for exactly these benefits. Our units can handle food waste from kitchens, cafeterias or gardens and turn it into useful soil amendments with little hassle.

For a complete guide, read Best Organic Waste Composter Machines: Expert Guide for India 2026.

What is Traditional Composting?

Traditional composting is the natural breakdown of organic waste by microbes in an open pile or pit. Common methods include:

- Windrows or Piles: Waste is heaped in long, exposed rows (windrows) outdoors. It decomposes over 2–4 months (or longer) depending on weather and turning.

- Pit or Trench Composting: Waste is buried in shallow trenches or pits. It’s simple and low-cost but also takes months and can attract pests.

- Vermicomposting (Worm Bins): Systems like the Subpod® are underground worm composters. Subpod uses worms and microbes to process scraps with “no odors, vermin or hard work of traditional composting”. These composters can be easier to use than open piles, but are still slower than machines.

Limitations: Traditional methods often require large space and careful management. They are slow (60–120 days), weather-dependent, and risk odors/pests if not managed well. Key drawbacks are:

- ❗ Slow turnaround: Takes 2–4+ months, so not ideal for tight deadlines.

- ❗ Large space needed: Open pits or windrows can require hundreds of square meters.

- ❗ Odor & vermin: Without cover, piles can smell and attract flies, rats or stray animals.

- ❗ Labor-intensive: Piles often need regular turning/shredding by hand or machine.

- ❗ Compliance issues: Uncontrolled piles may not meet strict waste rules without extra management.

In practice, many Indian facilities resort to simple pits or bins (like Subpod) for wet waste. However, these still face drawbacks of traditional composting. In contrast, mechanized composters solve many of these problems (see below).

Before making a purchase, explore these organic waste composter buying tips from leading manufacturers.

Side-by-Side Comparison: Key Factors

Facilities should compare critical factors when choosing an organic waste composter machine vs. traditional methods. The table below contrasts them on throughput, speed, footprint, costs, and more:

Organic Waste Composter vs Traditional Composting

| Factor | Organic Waste Composter (Machine) | Traditional Composting |

| Daily Capacity | Typically 0.1 – 3+ tonnes/day per machine. Modular systems allow multiple machines to scale capacity. | Small pits: ~0.1 – 2 T/day. Large windrow plants: 100 – 1000 T/day. Limited by land and labor. |

| Processing Time | Fast: Compost ready in 24–48 hours. | Slow: Usually 2–4 months (60–120 days). |

| Odor Control | Odorless: Enclosed system with filters/scrubbers. Suitable for indoor use. | Odor issues: Open piles often smell, especially in warm climates. |

| Pest Control | High: Sealed machines prevent rodents, flies, and insects. | Low: Open waste attracts flies, rats, dogs, and birds. |

| Space Requirement | Compact: Around 10–100 m². Suitable for basements, backyards, rooftops. | Large: Windrows need thousands of m². Even pits require large open areas. |

| Capital Cost (CAPEX) | High: Approx ₹6–40+ lakh depending on capacity and automation. | Low to moderate: Pits/windrows are cheap, but need land and equipment. |

| Operating Cost (OPEX) | Lower: ~₹100 per tonne (electricity + minor maintenance). | Higher: ~₹300 per tonne (labour, turning, monitoring, land upkeep). |

| Labour Requirement | Minimal: One operator for feeding waste and removing compost. | High: Regular turning, watering, monitoring, segregation. |

| Hygiene & Safety | High: Controlled temperature, enclosed, sanitized output. | Low to medium: Risk of pathogens, leachate, and unhygienic conditions. |

| Regulatory Compliance | Easy: Designed to meet SWM 2016 and often FCO standards. | Difficult: Must be carefully managed to meet pollution and waste rules. |

| Suitability | Hotels, hospitals, apartments, IT parks, municipalities, bulk waste generators. | Farms, rural areas, large open lands, small home gardens. |

As this table shows, organic waste composting machines outperform traditional methods in speed, space efficiency, and hygiene. Traditional pits may win on low initial cost, but they incur high labor and often fail strict regulations. In India, the Solid Waste Management Rules, 2016 even mandate on-site treatment for bulk waste generators, giving an edge to enclosed composters.

Learn how an organic waste composter transforms food waste into value through efficient on-site composting.

Which Facilities Benefit from a Composter (vs. Traditional)?

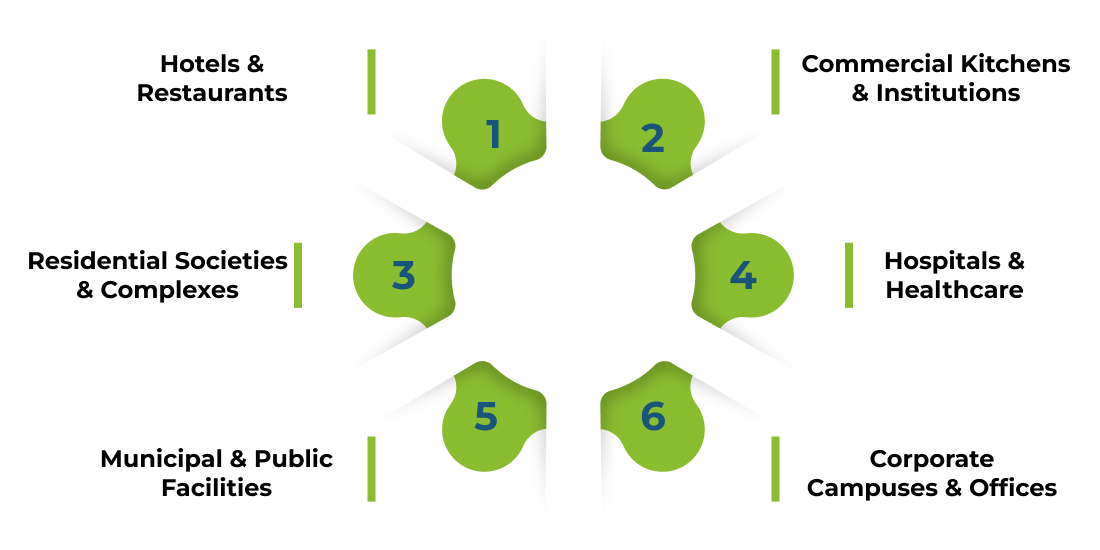

Organic waste composters are especially advantageous in settings that generate consistent, significant wet waste. Facilities that can benefit most include:

- Hotels & Restaurants: Large commercial kitchens produce hundreds of kg of food scraps daily. Many major hotels in India now use on-site composters. For example, Hilton DoubleTree Pune and Radisson Blu Guwahati each installed Kwik Composter machines (~100–1000 kg/day capacity) to turn kitchen waste into compost. This cut their landfill fees and created free fertilizer for landscaping. (EnvCure Technocrat LLP also supplies similar systems to hotel chains, integrating them seamlessly with kitchen operations.)

- Commercial Kitchens & Institutions: Corporate cafeterias, university dining halls, resorts and banquet halls. Any facility cooking at scale can avoid the hassle of piles. On-site machines keep kitchens clean and cut waste hauling bills.

- Residential Societies & Complexes: Apartment communities and gated societies often generate dozens of kg of kitchen waste per household. Instead of open compost pits (which odorize common areas), many societies in Mumbai, Bengaluru and Delhi are installing communal composters to handle the volume and odor. Decentralized composting agencies report that housing complexes are ideal candidates.

- Hospitals & Healthcare: Hospitals have cafeterias and organic discard (like cafeteria waste or garden clippings). Hygiene is paramount, so an odor-free composter helps maintain a clean campus. Some green hospitals in India compost up to 8 tonnes/day internally to meet “zero waste” goals (treating both dry and wet waste).

- Municipal & Public Facilities: Smart city wards, markets, schools, and community centers are increasingly equipping themselves with composting machines. For example, city programs in Pune and Ahmedabad use small-scale composters at schools and markets to reduce transportation of wet waste. Decentralized solutions help comply with SWM guidelines.

- Corporate Campuses & Offices: IT parks and corporate offices with large canteens also fit this profile. These campuses generate steady food waste and often aim to showcase sustainability (ESG) by composting on-site.

In each case, the alternative (windrows or open pits) either takes too much space, smells up the premises, or simply isn’t practical in dense urban settings. Organic waste composter machines solve these issues while producing useful compost.

Learn how an organic waste compost machine enables compliance with India’s Solid Waste Management (SWM) Rules.

How to Choose an Organic Waste Composter

If you’re convinced an organic waste composter machine could help, here’s a practical checklist for selecting the right unit:

- Waste Volume: Calculate your daily/weekly wet waste. Choose a machine with slightly higher capacity than this. (E.g. 150–200 kg/day machine for a big hotel kitchen).

- Automation Level: Fully-automatic machines (with built-in shredders and controls) are ideal for large generators; they cost more upfront but minimize labor. Semi-automatic or drum composters suit small to mid-scale sites (restaurants, hostels) and are more affordable.

- Space & Power: Ensure you have room (floor area and height) and electrical supply. Fully-automatic units may need 3-phase power and a forklift for installation. Semi-auto units are compact and may run on single-phase.

- Material & Maintenance: Look for durable, food-grade stainless steel construction and easy-access cleaning doors. Simple maintenance (emptying compost, periodic drum/drain cleaning) is essential.

- Odor Control: Verify the system has sealed chambers and activated-carbon filters or scrubbers for odor control, especially if installed indoors.

- Certification & Output Quality: Check that the unit’s output meets India’s Fertilizer Control Order (FCO) standards or local compost guidelines. A compliant machine can produce pathogen-free, nutrient-rich compost. Ask if the machine is approved for SWM-2016 compliance (most on-site composters are).

- Vendor Support: Choose a reputable supplier (e.g. EnvCure Technocrat LLP) that offers warranty, installation and training. Good vendors provide annual maintenance contracts (AMC) or service plans, plus quick support. Confirm after-sales service terms and spare-part availability.

- Budget & ROI: Balance the capital cost with expected savings. Cheaper drum units suit low budgets; high-end touch-screen composters pay off faster in large-scale use.

By matching a machine’s specs to your needs, you ensure efficient operation. For example, EnvCure offers Fully-Automatic Organic Waste Composter Machines for high-volume sites and Semi-Automatic Composters for smaller kitchens.

Discover how an organic waste composter benefits hotels and restaurants in day-to-day operations.

Case Study / Customer Story

Example: “Green Valley Hospital,” Bangalore (fictitious name). A large hospital with 1,000 beds and multiple cafeterias was struggling with ~300 kg/day of wet waste. Traditional compost piles smelled and needed full-time staff to turn and manage. EnvCure Technocrat LLP worked with them to install a 300 kg/day fully-automatic organic waste composter.

- Implementation: After a brief site survey, the composter was placed near the kitchen loading area. Staff were trained to segregate waste (plastic and metal removed) and feed the machine daily.

- Results: Within weeks, the hospital saw a 90% reduction in waste volume sent off-site. The machine processed each day’s waste to fine compost overnight. There were no foul odors or pests on campus. The generated compost (about 50 kg/day) was used in the hospital’s herbal gardens.

- Impact: The hospital cut its organic waste haulage costs by over ₹50,000 per month (saving fuel and tipping fees). It also gained “Green Hospital” credits in its sustainability reporting. Estimated ROI was under 2 years because disposal fees and purchased fertilizers dropped sharply.

This case reflects a common outcome: rapid payback and cleaner operations. Businesses that install these machines often advertise improved ESG credentials and employee satisfaction.

Next Steps & Call to Action

Ready to modernize your waste management? Here are practical next steps:

- Site Audit: Get a free waste assessment from EnvCure Technocrat LLP. Experts can measure your waste volumes and recommend the right model.

- Request a Quote: Ask for detailed pricing on the recommended organic waste composter (they offer fully- and semi-auto models). A formal quote will include CAPEX, OPEX and expected ROI.

- Download Spec Sheet: Review the technical specifications for machine sizes from EnvCure’s product pages (e.g. Fully-Automatic and Semi-Automatic organic waste composter). Use these in your budget planning.

- Pilot Run: Some vendors (like EnvCure) can arrange a trial unit or demonstration at your site. Seeing it in action helps staff buy in.

- Plan Integration: Consider logistics (where to place the machine, how to collect/pre-sort waste, and who will operate it). EnvCure offers installation and training as part of their service package.

Taking these steps will clarify costs and benefits for your specific facility. Investing in an organic waste composter can streamline waste handling and move you toward zero-waste goals. With EnvCure Technocrat LLP’s support, you can implement a turnkey solution – complete with audit, quote, and technical backup.

Conclusion

Choosing between traditional composting and an Organic Waste Composter depends on your facility’s size, space and needs. Small gardens might manage fine with pits or Subpod bins, but large hotels, hospitals and complexes will usually find machines more practical. Composting machines deliver rapid turnaround, better hygiene and regulatory compliance, all while producing valuable compost.

For most bulk waste generators in India, investing in an organic waste composting machine is a smart move for sustainability and cost savings. To explore options, contact EnvCure Technocrat LLP – they offer on-site audits, detailed quotes and downloadable spec sheets for their organic waste composter. Whether you need a fully-automatic 500 kg/day unit or a compact semi-automatic machine, EnvCure can help you design the right system. Take the next step toward zero-waste by requesting a consultation or quote today.

FAQs Related to Organic Waste Composter

Q. How much waste can an organic waste composter process per day?

Ans. Small units: 50–100 kg/day; industrial units: 0.1–3 tones/day per unit; scale by adding units.

Q. How long does it take to turn waste into compost in a composter machine?

Ans. Most machines convert food waste in 24–48 hours; usable compost typically in 1–2 days.

Q. What kinds of waste can go into a composting machine?

Ans. Kitchen waste (vegetable peels, fruit, cooked scraps, tea/coffee grounds); avoid large bones/wood; small paper.

Q. Will an organic waste composter stop odors and pests?

Ans. Yes, sealed, ventilated machines with filters are largely odorless and keep pests away when operated properly.

Q. Is an organic waste composter energy-intensive?

Ans. It uses electricity for motors/blowers (a few kW for commercial units); energy cost is often lower than transport/labor savings.

Q. What maintenance does a composter require?

Ans. Low upkeep: empty compost, occasional moisture, clean drums/filters, and periodic servicing or annual plans.

Q. How does a composter help with regulatory compliance?

Ans. On-site composting meets India’s SWM rules by treating waste at source; many units produce FCO-compliant compost.