Shredder machine is powerful destructive devices that break down materials into smaller pieces. They are essential to recycling and waste management, turning bulky or sensitive items, including fabric, plastic, office waste, or wood, into convenient fragments that may be disposed of or recycled. Shredder machine will cut or tear materials protecting sensitive information in document shredding while increasing resource recovery for recycling. This guide will go into the working of shredder machines, their main types and functions, and criteria for selection.

What Is a Shredder Machine?

A shredder machine ingests materials and mechanically cuts, tears, or grinds it into smaller pieces. Operating grimly in factories, the shredder deals with enormous volumes of waste, such as factory scrap, plastic containers, or textile wastes. An industrial shredder mostly operates with shafts equipped with interlocking blades and powered by a motor. For example, one heavy-duty textile shredder is “specifically engineered to efficiently shred waste textiles, including general plastic materials such as PVC, PP, and PE, ensuring effective recycling and waste reduction.” In all cases, shredders break down input material so that it can be disposed of, recycled, or reused easily.

Types of ShredderMachines

Shredder machines are produced in many types, each meant for different materials and industries. Some more common categories include:

- Office Waste Shredders: Commonly used in offices, these shredders turn documents into strips or cross-cut pieces (higher security) to avoid the theft of information.

- Industrial (Single-shaft) Shredders: Heavy-duty machines with a single rotor of blades; their domain is high-volume waste, wood pallets, plastics, cardboard, or e-waste. They run on a continuous basis and generally have a large hopper.

- Dual-shaft (Two-shaft) Shredders: They operate on two counter-rotating shafts; these rugged shredders have the capacity to take mixed municipal or bulky wastes and are largely available in waste-processing plants.

- Granulators: They function like shredders but have finer and high-speed rotating knives; generally, granulators are located downstream of a shredder to further granulate plastic or rubber to uniform granules.

- Specialized Shredders: These include tire shredders (for scrap tires), textile shredders (for textile wastes), metal shredders (like car or appliance recycling), and organic waste shredders (for mulch or compost). For example, “Waste Textile Shredders are therefore considered pivotal machines in the textile recycling process specially developed to efficiently reduce fabric waste into workable-sized pieces.”

- Wood and Green-waste Shredders: These machines are used in landscaping and forestry to shred branches and yard waste for use as mulch.

Each type is built for specific materials and capacities. The choice depends on what you need to shred and how much.

If you’re looking to tackle high-volume waste effectively, the Twin Shaft Shredder Machine for Municipal Solid Waste (MSW): A Smart Solution is designed for maximum productivity and longevity.

How Do Shredder Machines Work?

Most industrial shredders operate on the principle of one or two rotary shafts with blades or cutters fastened thereto. Material is fed into the shredding chamber either automatically (or by gravity) and is gashed and torn apart by the rotating blades.

For example, 30 kW motor running the blades can process tons of material per hour and still retain energy efficiency. Office Waste shredders work on similar principles applied to a much smaller scale: just insert office waste into a slot and rotating cutters slice it into strips (strip-cut) or into small pieces (cross-cut or micro-cut). Some shredders have multi-stage cutting or screens to specify the size of the trimmed-down product.

Safety features including sensors, emergency stops, and safety interlocks protect the user. Altogether, the motor power specification and design of the blades determine how effectively shredder can process different materials.

Advantages of Shredder Machinery

Using a shredder machine brings forth numerous advantages:

- Volume Reduction & Transit: Shredding is a process that turns big items into smaller fragments that drastically reduce volumetric observation. Garden chippers and plastic shredders, for instance, can convert big piles into shredded material. This “material may then be used for given applications such as insulation, stuffing, or as raw material for newer products.”

- Recycling & Environment-friendly: Shredders usually operate at the beginning of recycling processes. The shredded material after separating could be recycled more efficiently. Hence, in creating a circular economy, shredder machines “recycle wastes and reduce the use of landfills.” Dirt-shredded plastics or textiles are easier to clean and feed into recycling machines.

- Security: In offices or legal settings, a shredder is a mechanism to be used for destroying confidential data and information. High-security micro-cut shredders shred information so securely that it is practically impossible to retrieve it.

- Resource Recovery: Materials like metal or wood are usually sold by weight. Shredding waste of metal scrap or wood would allow their more efficient melting or composting, respectively, to recover value.

- Regulatory Compliance: Many industries have the legal requirement of being able to dispose of those wastes (medical or confidential records) securely. Shredders have appeared as one of the ironic alliances in the compliance of regulations.

- Cost Savings: Reducing waste volume leads to lower disposal costs. Shredded waste compact better in dumpsters or trucks. Moreover, reusing shredded material also prevents the company from purchasing raw material.

- Environmental Impact: By turning waste into a recyclable form, shredders help businesses attain sustainability goals and keep track of their carbon footprint.

Explore how the Industrial Shredder Machine: Turning Waste into Valuable Resources helps businesses recycle efficiently and reduce disposal costs.

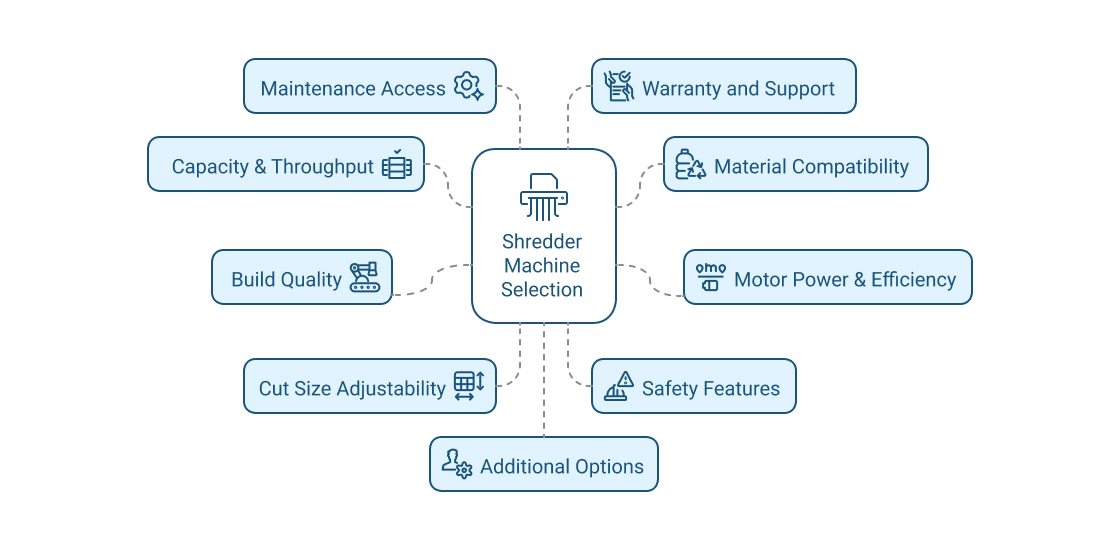

Key Features to Consider

When selecting a shredder machine, consider the following important factors:

- Capacity & Throughput: How much material can it process per hour? Shredders range from small office units to very big industrial models, ready to shred hundreds of kilograms per hour. Some textile shredders claim; “production capacity ranges from 500 to 6000 kg/h,” catering for heavy recycling needs. Match capacity with your volumes.

- Material Compatibility: Ensure the shredder and your specific waste agree (plastic, metal, wood, etc.). A large share of industrial shredders can accept a myriad of plastics (PVC, PP, PE) and fabrics but always consult the manufacturer regarding the specific intended uses of a model.

- Motor Power & Efficiency: Shredder motors vary in size (from a few kilowatts to hundreds). Heavy-duty motors shred harder materials, and they are built to process more materials. One should balance power and energy efficiency while making a purchase. For example, the 30 KW shredder offers high output “without compromising on energy consumption,” making it very economical and sustainable.

- Build Quality: A tough steel frame and quality blades ensure long working life and reliability. Manufacturers with good reputations always emphasize durability.

- Cut Size Adjustability: Some shredders allow changing the screen or even the blade configuration for different shred sizes. Adjustable shred settings provide great flexibility depending on whether coarse or fine output is required.

- Safety Features: Should have them, including emergency stop buttons, safety interlocks on hoppers, and warning systems. Heavy industrial shredders should have guards and lock-out mechanisms.

- Maintenance Access: Easy access to cleaning and blade maintenance lowers downtime. These shredders are subject to periodic blade sharpening or replacement.

- Warranty and Support: Look for manufacturers who offer solid warranties and after-sales customer support. A good warranty means the manufacturer stands behind their quality and serves as a shield for your investment.

- Additional Options: Custom voltages, load-feeding options, and intelligent controls come in handy. Also consider noise levels (important for office shredders) and mobility (wheels or stationary).

Waste Shredder Machine

Waste shredders are those shredders which have been made especially for processing waste materials (municipal or industrial). Usually, these machines deal with all sorts of mixed or bulky wastes, including plastics, woods, organics, and textiles. By shredding waste into uniform pieces, they ready them for recycling or further processing, such as composting or sorting down the line. Textile or fabric waste when shredded by industrial machines could perhaps be re-spun or used as an insulator.

The shredder is used together with sorting and compaction in solid waste management: the shredder reduces volume and increases the uniformity of the materials, thus enabling better downstream efficiency. In short, waste shredders turn complex garbage streams into manageable fractions for recycling, aiding environmental concerns.

Maintenance and Safety

Regular maintenance is the core to ensure the shredder will operate efficiently, is extended and proper care. This includes clearing all types of jams, blade sharpening, and cleaning out debris accumulated on it. Manufacturers specify, “The regular maintenance such as blade sharpening and cleaning is critical for the highest performance and longevity.” Carry out lubrication and inspections of parts as per the manual. Check filters if applicable. For safety, never put your hand in the shredding chamber while it is running. Always follow lock-out/tag-out (LOTO) procedures to carry out repairs. Sometimes an industrial-grade shredder will come equipped with emergency-stop buttons and safety interlocks- activate these if there is abnormal noise or an overloading event. Train operators on best practice for safe use (e.g., material should be fed slowly and never force any oversized items). With maintenance on one side and safety procedures on the other, companies maintain productive and safe shredders.

Choosing a Shredder Machine Manufacturer

Choosing a shredder machine manufacturer is not easy. Whereas a reputable manufacturer guarantees your shredder will perform as promised and will last, an unreliable one will probably shortchange you. Grab a company like EnvCure Technocrat LLP that has experience in your industry or whose machines are tested under legitimate safety standards. Reputable manufacturers stress important features such as durable construction, adequate testing, warranty, etc.

For Example, EnvCure Technocrat LLP offers industrial single shaft and twin shaft shredders built from high-quality materials and backed by after sales support. Check whether the manufacturer offers any documents supporting claims (test reports, certifications) and after-sale service (installation, spare parts, etc.).

Can the manufacture also accommodate any customization for your needs (voltage or blade configurations)? Packaging and delivery methods (wooden case for shipment) shall also speak volumes for professionalism. In short, try to find some reviews or case studies on the machines they manufacture and go with a supplier ready to back their product with support and training.

FAQs Related to Shredder Machine

Q: What materials can a shredder machine process?

A: Many industrial shredders handle a wide range of materials. For example, textile waste shredders can process fabrics, clothing, and fibers. Plastic shredders handle PVC, PP, PE, etc. Paper and cardboard shredders are built for pulp. Always check the machine’s specs: robust shredders may also handle wood, rubber (tires), light metal, or mixed municipal waste.

Q: How does a shredder machine help sustainability?

A: By recycling waste and reducing landfill use, shredders promote a circular economy. Shredding turns discarded materials into smaller pieces that can be reused or recycled. For instance, shredded plastic can be melted and remolded, while shredded textiles can become insulation or stuffing. This reduces raw material consumption and minimizes environmental impact.

Q: What features should I look for in a shredder?

A: Key features include adjustable cut size, motor power, and safety controls. You’ll want a machine whose capacity matches your volume needs, along with safety interlocks and an emergency stop. Durable blades and a strong motor (e.g. tens of kW for industrial machines) are important. Also look for ease of maintenance, warranty coverage, and quality construction.