Waste management is an integral part of any manufacturing or production-related industry. It is even practical for any other businesses as waste management helps lower environmental impact and, at the same time, helps in cost reduction.

Basically, a shredder is a machine, a system that is used to reduce the size of the material. It is used to scrap metal, e-waste recycling, plastic recycling, wood recycling, and even tire-shredding.

Volume reduction of bulky materials and items is all done using the shredder machine. So when it comes to recycling, shredders are the best options. Shredded items can even be directly put into processes as raw materials.

Even for micro-waste management, shredders can be used. How? In private micro-communities and hubs, recycling programs with proper shredding equipment can be incorporated. This also has the potential to bring in substantial revenues and provide secondary income streams.

Types of Shredders

Shredder machines vary from type to type based on their uses and requirements in the industry. The internal processes may be different and vary based on the materials that the machine would be handling. Let us know more about the different types of shredders:

Twin-shaft shredders

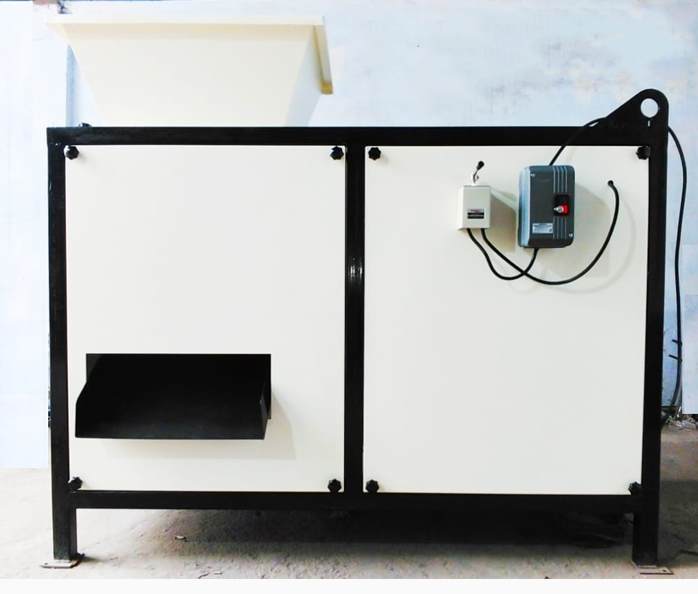

This is a customized shredding machine developed by the EnvCure team, especially to manage industrial waste and recycle it. It uses two sharp steel blades to shred the waste, reducing waste management time. This type of shredder is suitable for medium to heavy-duty waste such as tyres, tin boxes, metal waste, etc. Moreover, being managed by two blades, it does not require a perforated method.

Grinder

Using abrasion and compression, grinders are often used for pulverization and crushing materials to create granular products. Wheels, drums, and plates can be used in these processes.

Chippers

Chipper shredders use high-speed rotary knives to reduce the materials to mere chips and flakes. They are fed manually or sometimes automatically, both.

Granulators

Mainly granulators are used for plastic recycling. These shredders reduce parts and trim them for reuse in the production lines. Granulators are available in different sizes with different mechanics based on their industry type, materials, and geographic locations.

Hammermills

These are again used to pulverize, crush and shatter materials. The most common configuration is where it has a chamber with a rotary drum with swiveling hammers. This is a gravity-fed chamber, and the output screens can control the size of the particles.

Specialty Shredders

They are designed for particular types of materials. These shredder machines can be a combination of any of the above-given types per the users’ requirements.

Another primary type of shredder machine is the twin shaft shredder machine. They are versatile and designed for shredding bulky materials in their preliminary stage. These twin shaft shredders are extremely rugged with a strong support structure for withstanding all loads.

The twin shaft shredders are usually available in a wide range of electric and hydraulic drive configurations.

PET bottle shredder machines are available on the market for crushing and recycling plastic into granular form. These machines are the most suitable for municipal waste management.

The use of shredders in waste management and recycling

- Asphalt, rubber, wood, plastic, and similar materials can be condensed quickly to mere fractions.

- Properly shredded materials can be buried in landfills.

- Shredders help reduce the materials’ volume and help decrease storage costs.

Each shredder has a different usage for different types of materials, industries, and locations. But, one of the most critical and common usages is the fact that it helps in reducing environmental waste significantly.

Frequently Asked Questions:

Q.1. What is the function of a shredder in e-waste management?

Ans. A shredder is a machine or equipment used for shredding. Shredding systems are used to reduce the size of a given material. While most online dictionaries define the shredder as “a device used for shredding documents as a security measure to prevent identity theft,” shredders can be of many types based on the material being processed.

Q.2 What is shredding Technology?

Ans. A shredding technology is a machine that is utilized for shredding. A shredding machine is utilized to decrease the size of material by tearing or cutting it into shreds. The shredding procedure creates raw material to be introduced again into the production stage and finished goods.

Q.3 What Types of Materials can be shredded?

Ans. Plastics, wood, rubber, asphalt, and similar materials can be immediately reduced to a mere fraction of their original size, and many can be sold or given directly back to the public for distribution as useful products.